FEM analysis

In combination with CAD, the Finite-Element-Method is the most powerful tool to rationalize the engineering work and to optimize quality. The following analysis options are available in structural mechanics:

- Static analysis

- Buckling analysis

- Modal analysis

- Iterative optimization

- Fatigue/ life-time assessment

- Dynamic analysis (time, frequency, stochastic response, shock)

- Non-linear analysis (contacts, elastic-plastic and hyper-elastic materials

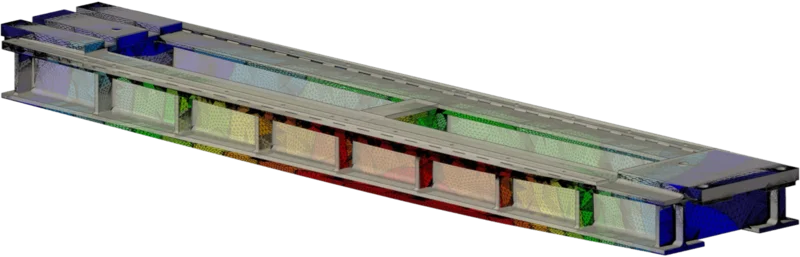

Static Linear Analysis

Static linear analyses covers a wide range of applications to determine displacements and stresses/strains within the elastic material properties. In addition to the displacement of a component under a defined load, the permissible forces for a specified maximum deflection can also be determined.

- Displacement (within the elastic material properties)

- Stress / Strain (within the elastic material properties)

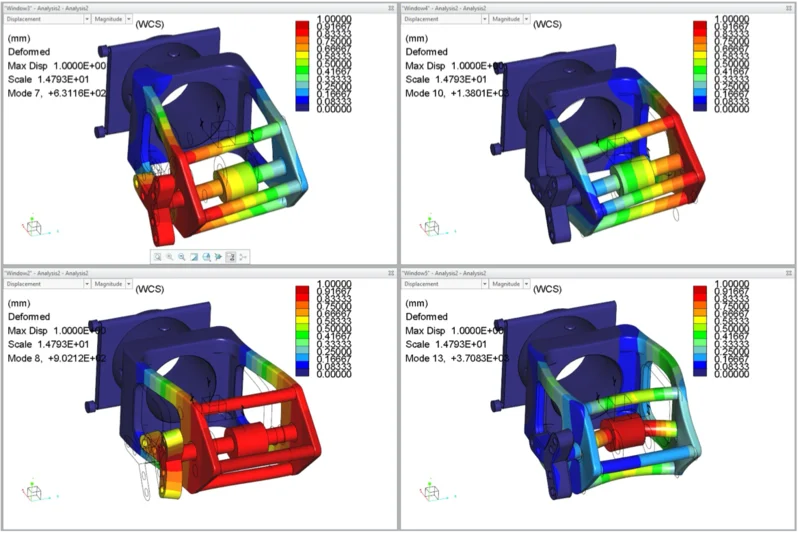

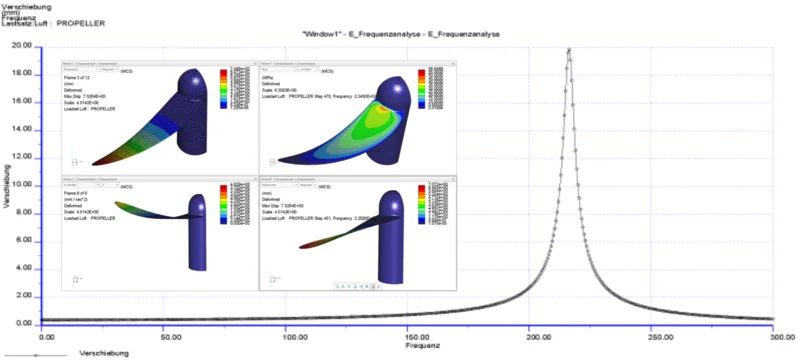

Modal Analysis

This analysis allows us to check single parts or assemblies for resonances or unwanted frequencies. It can also be used to get an idea of overall stiffness and to identify areas for improvement. The modal analysis also defines the basis for additional dynamic simulations.

- Natural frequency

- Modular form

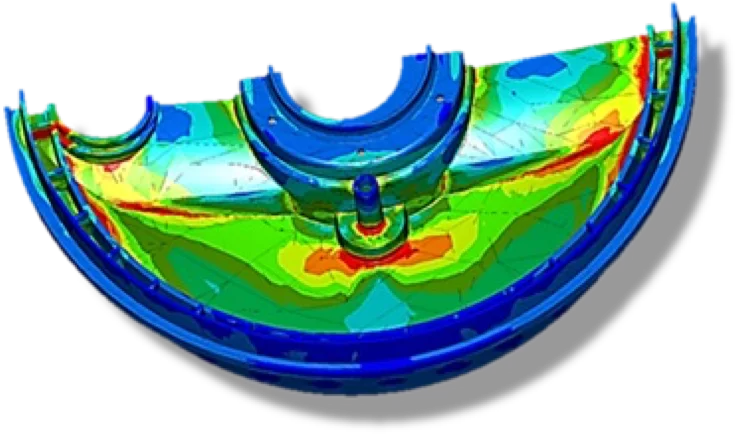

Welding

Calculation and design of a welded joint using the structural stress method CAB with cut out weld roots forms the basis for the safe design of welded assemblies. This enables us to simulate a realistic flow of forces in the welded assembly. An additional assessment according to FKM is possible.

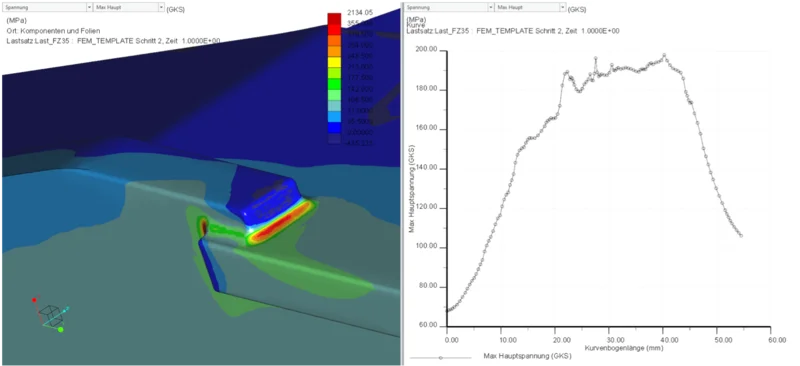

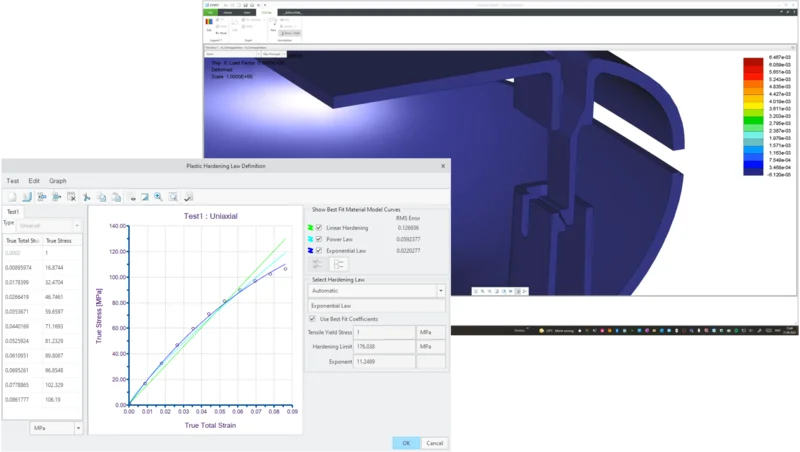

Static Nonlinear Analysis

Displacements and stresses/strains beyond the elastic material properties require the use of a static, nonlinear analysis. With nonlinear options such as large deformation, contacts, elastoplastic and hyperelastic materials, complex component displacements can be examined realistically.

Dynamic Analysis

Dynamic analyses are essential to determine the component strength under time-varying loads. With response analysis in the time and frequency domain, stochastic response analysis through to dynamic impact analysis, we can provide you with a wide range of dynamic analyses.

- Dynamic Time Response

- Dynamic Frequency Response

- Dynamic Random Response (PSD)

- Dynamic Shock Response

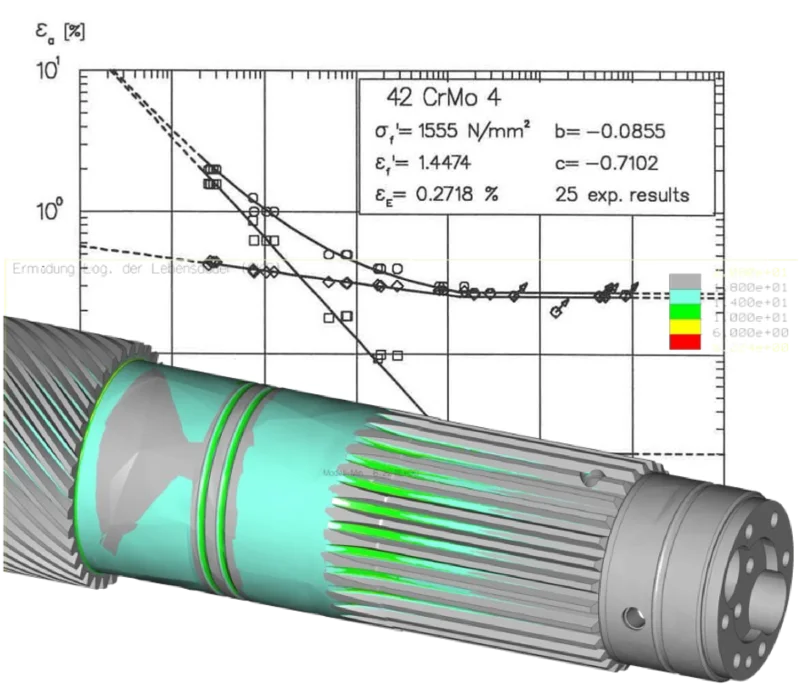

Fatigue Analysis

- Proof of fatigue strength

- Proof of engineering strength

- Analysis of vibration-loaded components and assemblies in LCF, HCF and VHSF

- Use of real test data

- Durable dimensioning of components and structures

- Verification according to standards (FKM, Eurocode)

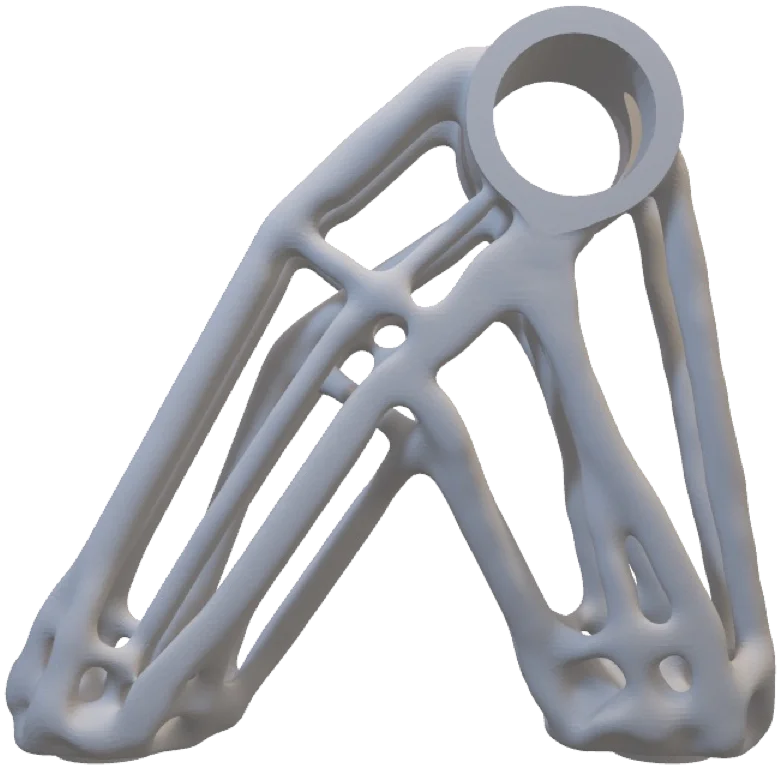

Topology optimization

Computer-aided optimization of the geometric shape plays an important role in component development. Used right at the beginning of a design process, allows ideas for an application-optimized geometry to be considered. Early and intelligent shaping can save material and, accordingly, later component weight and material costs.

- Design spaces

- Load and operating conditions

- Target weight and mass reduction

- Materials

- Manufacturing methods

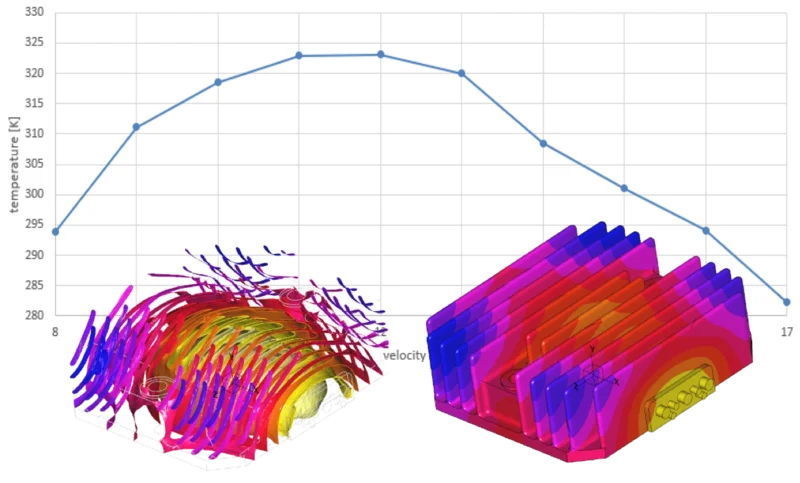

Thermal Analysis

- Steady-state and transient

- Structural deformation due to thermal influence

- Integration with CFD

- Temperature profile of components in a flow

- Heat transfer in liquids and solids

- Temperature profiles at points of measurement